experience POLYURETHANE EXPERTISE

Custom-Molded Castable Urethane

Custom-Molded Castable Urethane | Available Nationwide

Serving Industry with Custom Molded Urethane

Urethane Specialties manufactures molded and machined polyurethane (liquid cast polyurethane elastomers) products for industry. Polyurethane (sometimes called just urethane) is resistant to harsh chemicals and abrasion.

Urethane Specialties, located in Goodlettsville, TN just north of Nashville, makes custom molded urethane products using high grade liquid cast polyurethane resins.

Our polyurethane products range from custom molded shapes such as gear cogs, abrasive resistant nozzles, automotive bushings for classic cars and tapered rollers to stocked items such as polyurethane sheets and pads, polyurethane round bar, polyurethane tubing and polyurethane square bar stock of various dimensions, hardnesses and colors.

Sheets and Pads

Urethane Specialties makes polyurethane sheets and pads 24" x 48" with thicknesses of 1/32", 1/16" and 1/8" as well as custom sizes.

Rods

Urethane Specialties manufactures polyurethane rods in many "stock sizes" with diameters from 3/4" to 7" and in lengths ranging from 1 foot to 3 feet. Other sizes can be custom built as well.

Squares and Rectangular Bars

Urethane Specials makes polyurethane squares and rectangular bars by pouring high grade liquid cast polyurethane resins in open cast molds.

Tubes

Urethane Specialties uses high quality urethane (high grade liquid cast polyurethane resins) to manufacturer polyurethane tubes in various sizes.

Custom Molded Items

We take pride in our ability to offer this type of service along with our competitive pricing. Please contact us about your custom part needs and we will create a urethane solution for you!

Haven Machine Rollers

Urethane Specialties makes polyurethane replacement feed rollers for Haven machine tube cutting 871, 872, and 873 'dual-blade' models. These rollers are made from the highest quality urethane available at prices below that of the manufacturer.

EXPERT URETHANE SOLUTIONS

Revolutionize Your Business processes

Since 1976, Urethane Specialties has been a beacon of excellence. Founded by the Trew brothers, our journey began with polyurethane wheels and grew into a thriving custom urethane business. Led by Scott Trew, we've evolved and now operate from a spacious 15,000-square-foot facility in Goodlettsville, TN. Our commitment to quality, service, and competitive pricing has earned us a loyal customer base nationwide. Experience our unmatched expertise—contact us today!

Revolutionize Your Business processes

Prototyping to Manufacturing

Our prototyping and manufacturing processes are a testament to efficiency and quality. We meticulously refine your concepts, swiftly transitioning from prototype to full-scale production. This streamlined approach ensures that your vision becomes a reality in record time without compromising on precision or performance. Experience the rapid transformation of ideas into tangible success. Contact us today and witness the power of seamless innovation.

uncover the benefits of Urethane

Peerless Versatility, Durability, and Performance

Surpassing plastics, steel, rubber, and aluminum, urethane excels in withstanding abrasion and impact. Its flexible properties, extended service life, and exceptional grip make it the superior choice over alternative materials. Elevate your products by opting for urethane.

Abrasion Resistance

Urethane showcases remarkable resistance to abrasion, outperforming alternative materials, and guaranteeing enduring durability.

Adhesion

Thanks to its outstanding adhesion properties, urethane establishes robust connections, elevating product dependability and overall performance.

Compression

Due to its exceptional adhesion characteristics, urethane forges robust connections, thereby enhancing both product reliability and performance.

Environmental Resistance

Urethane showcases remarkable resistance to environmental challenges, ensuring consistent performance and durability even in adverse conditions.

hardness

Urethane displays exceptional hardness, outperforming metals, plastics, and rubber in terms of both durability and performance.

and much more

Explore the extensive potential of urethane, delivering unmatched versatility and performance across a diverse spectrum of applications and industries.

Delivering Quality Urethane Components Across Industries

At Urethane Specialties Inc., we're dedicated to crafting tailor-made polyurethane solutions to meet the distinct requirements of various industries. Leveraging our extensive experience and cutting-edge manufacturing techniques, we provide high-performance polyurethane products designed to excel in diverse sectors. Discover the versatility of our polyurethane solutions and elevate your industry with us.

industries of Expertise

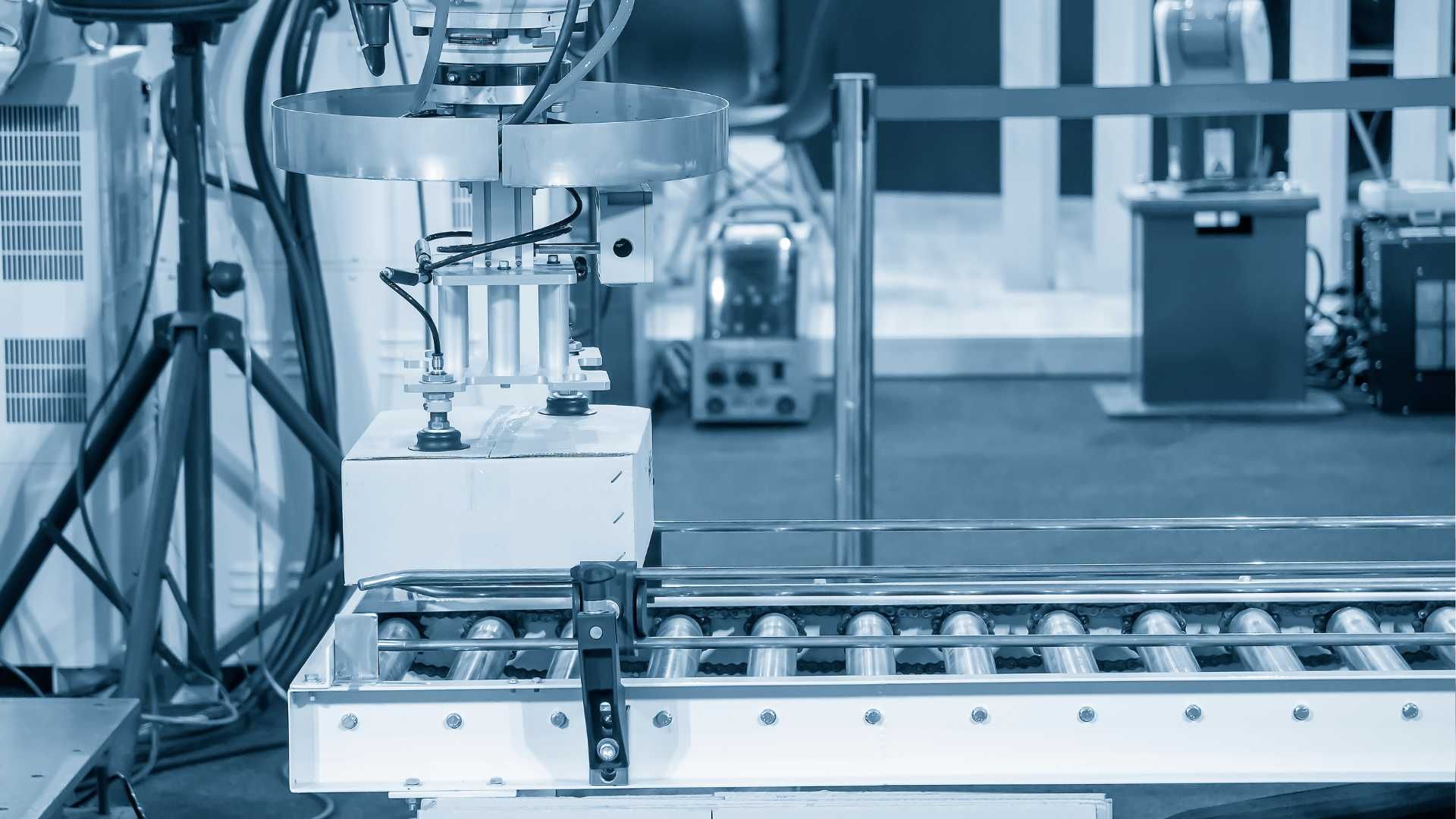

Material Handling

Enhance material handling equipment production with our dedicated polyurethane components, such as rollers, clamps, diverters, and wheels.

Applications

Explore our extensive selection of premium polyurethane products suitable for a variety of uses, including deskew rollers, gears, drive belts, bushings, and more.

Uncompromising Quality

We are dedicated to upholding the highest standards of quality. Our unwavering commitment to rigorous manufacturing processes and the use of premium materials ensures the reliability, durability, and outstanding performance of our products. We recognize the paramount significance of quality in fulfilling industry requirements. Discover the distinction that our top-quality urethane products can make for your business today.

Custom Colors, Tailored to You

At Urethane Specialties, we believe in giving you the freedom to choose. Instead of restricting you to specific colors based on hardness or type, we let you pick the color that suits your requirements best. Our standard color options include black, red, blue, orange, tan, green, and yellow. If you have a specific hue in mind that's not listed, we're more than willing to accommodate your needs. Please keep in mind that our clear option may shift to an amber tone based on the type of urethane used. Customize your polyurethane products today to match your unique preferences and applications.

FREQUENTLY ASKED QUESTIONS

-

Why is Urethane Specialties Inc. so popular?

Urethane Specialties Inc. is the go-to choice in Goodlettsville, TN, as a leading polyurethane manufacturer. Our popularity stems from our unwavering commitment to quality and innovation. As a polyurethane manufacturer, we deliver custom solutions that stand out in the industry. With a track record of excellence, our customers repeatedly choose us for their polyurethane manufacturing needs. Our team of experts combines years of experience with cutting-edge technology to produce high-performance polyurethane products. This dedication to quality and precision sets us apart from the competition, making us the preferred polyurethane manufacturer in Goodlettsville and beyond. Whether it's for industrial applications, automotive components, or any other sector, our polyurethane solutions are trusted for their durability and performance. Join our satisfied customers today and experience the excellence that makes us the preferred polyurethane manufacturer in the region.

-

Do you have a glossary of urethane-related terms?

We sure do! Here is a list of commonly used terms we use in the industry. If you have any questions, please don't hesitate to reach out to us.

- Additives: Materials combined with VIBRATHANE and curatives to modify the properties of the roll, such as plasticizers, fillers, and stabilizers.

- Bashore Resilience: An ASTM test (D-2632) for the rebound characteristics of the elastomer. High Bashore resilience generally implies low heat buildup in the roll when used at high speeds under high loads.

- Colorants: Dyes or pigments that provide color to the roll compound.

- Compression Set: The characteristic of the elastomer to remain permanently deformed after deforming forces are removed. VIBRATHANE roll prepolymers offer a low compression set for excellent dimensional stability in the roll.

- Curatives: Materials that react with VIBRATHANE prepolymer to produce the final elastomer. Examples are TMP, TIPA, and Isonol 93.

- Durometer: The hardness of the final elastomer or the gauge used to measure the hardness. The Shore A scale (ASTM D-2240) is commonly used.

- Elastomer: The solid rubber compound that constitutes the final roll cover.

- Fillers: Solids added to the roll compound, generally to improve its grinding characteristics or physical properties.

- Hydrolytic Stabilizers: Additives that extend the service life of roll compounds exposed heavily to water.

- Modulus: The stiffness of an elastomer is typically measured as the force required to stretch a strip of the elastomer to a given extent. Modulus is closely related to hardness.

- Mold Release Agent: A lubricant that prevents the roll surface from adhering to the mold.

- Polyester: A chemical building block that reacts with TDI to produce VIBRATHANE roll prepolymers. The polyester provides good solvent resistance and good mechanical properties in the final elastomer.

- Polyether: A chemical building block used in place of polyester in some VIBRATHANE prepolymers, e.g., B-600 and B-615. The polyether provides outstanding resilience and hydrolytic stability.

- Polymer: The solid polyurethane rubber produced from the chemical reaction of VIBRATHANE prepolymer with curative. The final roll compound often also contains additives such as plasticizer or filler that are dissolved or dispersed in the polyurethane polymer.

- Polyurethane (Urethane): The polymer (rubber) is prepared by reacting a polyisocyanate (VIBRATHANE prepolymer) with a polyhydroxy-terminated compound (curative). The word urethane can often be misspelled. Some incorrect spellings include urithane, urathane, urothane, and eurothane. There is only one correct way to spell this word: URETHANE.

- Primer (Adhesive): Material that bonds the VIBRATHANE roll compound securely to the core of the roll.

- Tear Strength (Split Strength): A measure of the resistance of the elastomer to tear and gouging. This property is generally related to resistance to abrasion.

-

What is the best way to contact you?

You can reach us by calling (615) 851-9401, emailing urethanespecialties@gmail.com, or using the contact form here on our site.

We can't wait to hear from you!

PARTNER WITH US TODAY

Eager to enhance your sector with our bespoke polyurethane solutions? Reach out via the form below and let us help you meet your unique requirements. Discover quality, durability, and top-notch performance today!

Contact Us

We will get back to you as soon as possible.

Please try again later.

Polyurethane Manufacturer

Contact Us

© 2023 All Rights Reserved | Urethane Specialties Inc.